Catalog

search products

online service

TEL: +86-731-28679679

FAX: +86-731-28679979

Mobile: +86 139 0733 7319

E-mail: info@hvr-magnet.com

Optimize your production speed with HVR Magnet mold change systems

It is not hard to imagine that there always extra time and energy is wasted during use traditional mechanical and hydraulic clamping system. Extra time and energy is spend on looking proper clamp part and fasten on the mold

HVR is currently the most comprehensive answer to the growing requirement of JIT (just in time), SMED (Single-Minute Exchange of Die) in all advanced manufacturing processes facing smaller batch runs and wider product ranges.

If you're looking for the maximum flexibility, rapidity and quality of the molded parts HVR magnet quick mold change systems is the right choice for your injection molding machine, die casting machine, punching machine.

Brief introduction of HVR electro permanent magnet for quick mold change

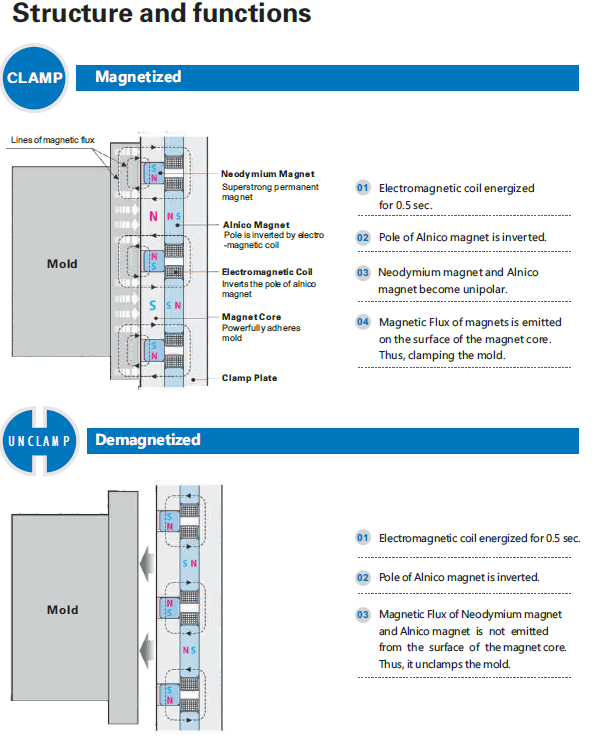

Electro permanent system is intrinsically safe being not affected by any electrical power failure. Magnet high energy coming from the permanent magnets keeps the uniform clamped with safety and easily. That is to say, even during a power failure, the system remains operative, with constant clamping force.

Magnetic flux penetrates the die only 20mm deep. The mold / die face and part cannot become magnetized, allowing for scrap removal, and proper die operation without interference. In a few seconds with the simple press of a button, it is possible to clamp or unclamp the mold / die in complete safety

Unique magnet system technical advantage

High quality through total uniformity

With conventional systems, the mold get clamped on its perimeter, thus generating tensions and deformation resulting in deflections during production, due to the opening effort and to the weight of the mold.

A magnetic system provides an uniform clamping all over the contact surface. No movement of the mold translates immediately in better quality and repeatability of the molded parts and it prevents also the over-packing phenomena

Reducing costs

The complete management process of inventory can be optimized. The space available will be better utilized. Not anymore need to manage clamps, bolts, consumables hardware, dedicated tooling No more oil disposal and maintenance. Responsibility for the hydraulic circuits. No hidden costs.

Quick pay back

The limited investment and the great operative convenience can grant a quick pay back, that in some cases it may be just a few months. System value will remain high even the end of the machine life.

Comparison table between magnet clamping and traditional clamping

.png)

HQMC Magnet clamping applied in injection mold machine real picture