Catalog

search products

online service

TEL: +86-731-28679679

FAX: +86-731-28679979

Mobile: +86 139 0733 7319

E-mail: info@hvr-magnet.com

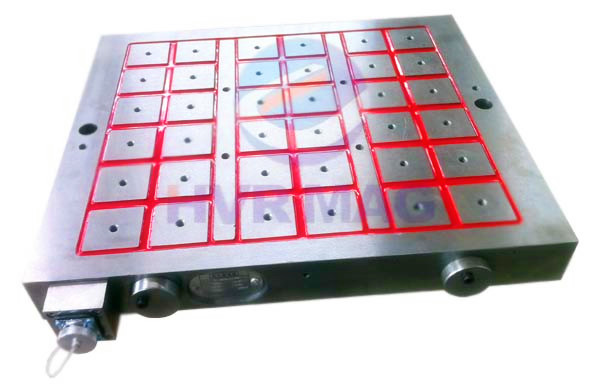

The electro permanent magnetic chuck for Machining center that design and manufacture by HVR Magnetic is the best magnetic solution In china currently, the HVR MAGNETIC design and manufacture electro permanent magnetic chuck can be widely used for various types of CNC machining center, the HVR MAGNETIC company not only bring perfect solution to the traditional clamping tool defect, but also take new revolution of modern machine tool.

The electro permanent magnetic chuck that HVR MAGNETIC design and manufacture is the ideal choice for modern machining, can let the processing very efficiency and the finished work piece with high quality. It is the is the ideal choice for modern machining industry. The HVR MAGETIC Company using European technology and also the leader in the electro permanent magnetic application. The HVR MAGNETIC is the first brand of electric permanent magnet sucker in china.

By using the European advanced electric control permanent magnet technology, The HVR MAGNETIC chuck can holding the work piece only rely on the powerful neodymium iron boron permanent magnetic force, while the current change, the magnetic force without any effect. And the Process also does not generate heat; the surface of the suction force is even. Consider these characteristic, these advantages are conducive to improve the machining accuracy.

The strong type electro permanent magnetic chuck only needs power in the magnetizing and demagnetizing process. While in the other period, do not use any other energy. By using the unique internal structure design, the magnetic chuck impact resistance, can fulfill zero fault requirements and the maintenance cost is also very low. These advantages are favorable to reduce machining cost, achieve zero-cost operation。